In the world of manufacturing, speed and precision can make or break competitiveness. Yet, for many leading factories whether in pumps, cycles, or metal forming—the reality was far from ideal. Production lines often ran into hidden bottlenecks, supervisors were left firefighting with outdated reports, and decision-makers had to rely on incomplete data that reached them days too late. What looked like a smooth-running operation from the outside was actually weighed down by inefficiencies that quietly drained productivity and profits.

That’s when these manufacturers decided to partner with Ausweg. By integrating our OEE solution for manufacturing efficiency through IIoT-driven monitoring and automation solutions, they shifted from working in the dark to operating with real-time clarity. Downtime that once went unnoticed was now tracked instantly. Performance gaps that previously took days to uncover became visible within seconds. With data flowing seamlessly across teams, decision-making accelerated, productivity soared, and what were once blind spots turned into powerful opportunities for continuous improvement. Learn more about our OEE solution for manufacturing efficiency and how it can transform your operations.

Tracing the Bottlenecks

What if you’re losing an hour of production every day per operator — and not even realizing it?

This was the silent challenge faced by one of our manufacturing clients. Despite having skilled operators and robust processes, critical inefficiencies were slipping through the cracks:

- No real-time visibility into shop floor performance

- Frequent delays in decision-making due to outdated data

- Production losses going unnoticed for days

- Manual escalations for downtime tracking

- High dependency on supervisory staff for data collection

- Fragmented reporting across departments

- Zero traceability on production bottlenecks

- Inefficient shift handovers with no root cause analysis

The gaps became even more evident when reviewing daily operations:

- Shifts officially began at 8:00 AM, yet the first product rolled out only after 30 minutes. In reality, the production cycle time for one product was just 1 minute—revealing a hidden gap that silently drained productivity every day.

- Similarly, although shifts were scheduled to end at 4:30 PM, operators often wound down and left by 4:00 PM resulting in a consistent 30-minute loss of productive time at the close of every shift.

- This added up to nearly 1 lost productive hour per operator per day — an invisible drain on efficiency and output.

The core application: Overall Equipment Efficiency (OEE)

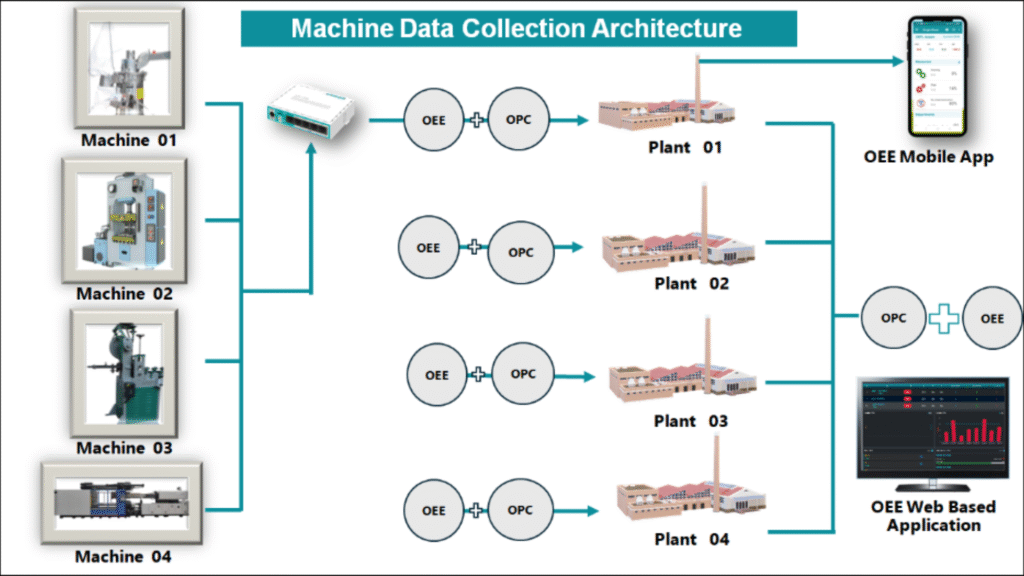

Ausweg’s OEE solution delivers precise, actionable insights tailored for pumps, cycles, and metal forming operations:

- Real-time tracking of machine uptime, downtime, and production cycle efficiency

- Automated logging of production counts, scrap rates, and quality losses

- Shift-wise and operator-wise visibility for enhanced accountability

- Early detection of recurring issues to prevent unplanned downtime

- Cross-machine and plant comparison to identify improvement opportunities

Behind the Transformation: What Real-Time Data Delivered

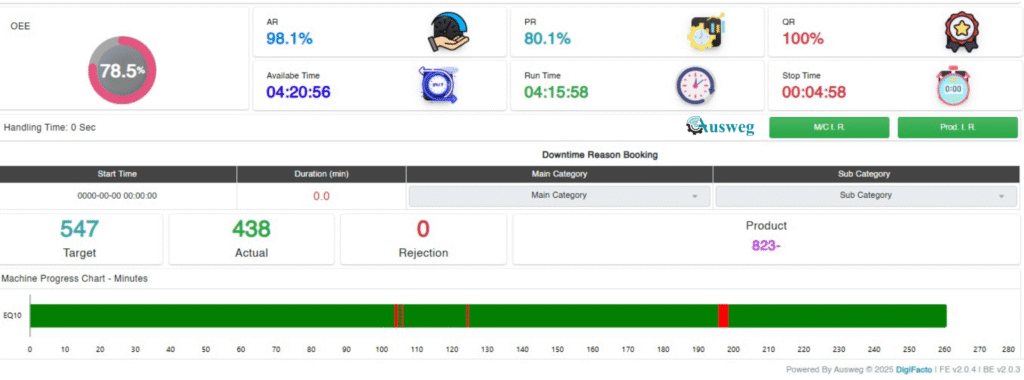

After deploying Ausweg’s OEE (Overall Equipment Efficiency) solution, the client achieved:

- Live dashboards showing performance metrics across the plant

- Proactive alerts and auto-escalations for downtime events

- Centralized platform for production reporting and analytics

- Data-driven shift handovers with root cause insights

- Digital workstations empowering operators to act in real time

- Automated tracking of shift start/end times with punctuality enforcement

- Unified, plant-wide visibility on a single intuitive screen

- Cross-plant benchmarking to identify which facility performed better, why others lagged, and how to improve efficiency across all plants.

Impact & Results

- 23% increase in OEE efficiency within just 5 months

- Shift optimization: reduced from three shifts to two, without losing output

- 180+ man hours saved per month by eliminating manual data entry

- Significant reduction in downtime during shift changes

- Higher accountability with late starts and early exits automatically flagged

- Seamless SAP integration with automated, on-time data posting

- CapEx avoidance by fully utilizing existing assets, removing the need for additional machinery

This transformation not only addressed the client’s immediate operational inefficiencies but also created a culture of real-time accountability and performance-driven decision-making. By harnessing Ausweg’s OEE solution, the manufacturer unlocked sustainable efficiency gains, reduced waste, and future-ready operations — all without major capital investments.

Ready to Optimize Your Shop Floor?

Discover how Ausweg’s OEE solution can help your business eliminate blind spots, boost productivity, and maximize efficiency.

Leave a Reply