Transform your factories with a top IIoT solution provider

Industrial IoT is the key to future manufacturing, allowing factories to seamlessly integrate automation, data-driven insights, and real-time optimization.

Industries that gained value from the industrial internet of things

Industrial IoT enables industries to achieve more efficiency, cost savings, and seamless digital integration for smarter decision-making and innovation.

Automotive

Pharma

Steel

Paper

Electronics

FMCG

Aerospace

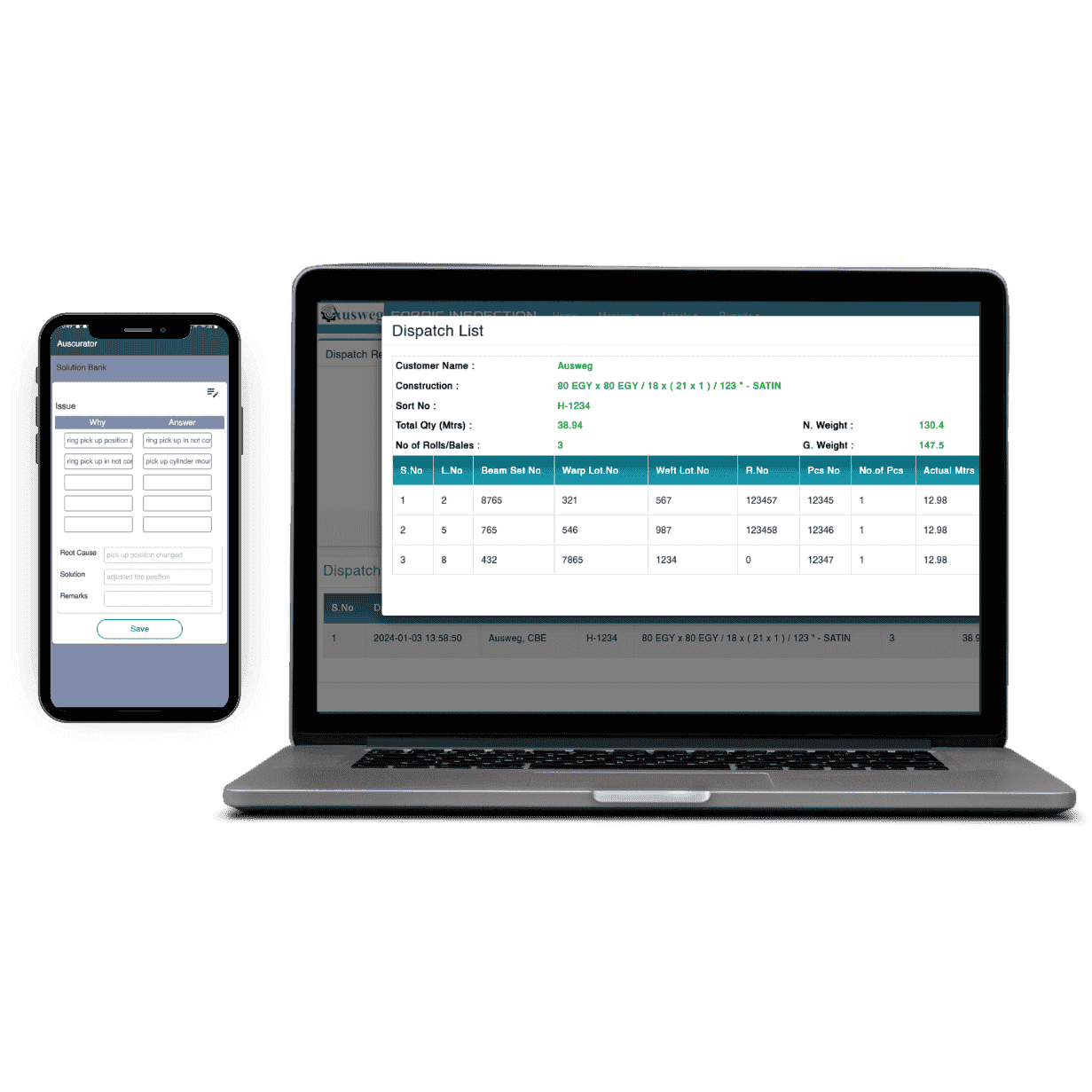

Textile

Others

Sugar

Start Your Industry 4.0 Journey

Assess Your Current Digitalization Level and Discover Potential ROI

→ Industry 4.0, also known as the Fourth Industrial Revolution, is the integration of intelligent digital technologies into manufacturing

→ IIOT Supervisory Control and Data Acquisition (SCADA) provides more extensive industrial insights and automation.

Assessment Tool: Online assessment to help companies understand their current Industry 4.0 readiness.

Key Customers

Explore the industries and businesses benefiting from IIoT solutions to improve productivity, reduce downtime, and maximize performance.

Technology Partner

Our Products

-

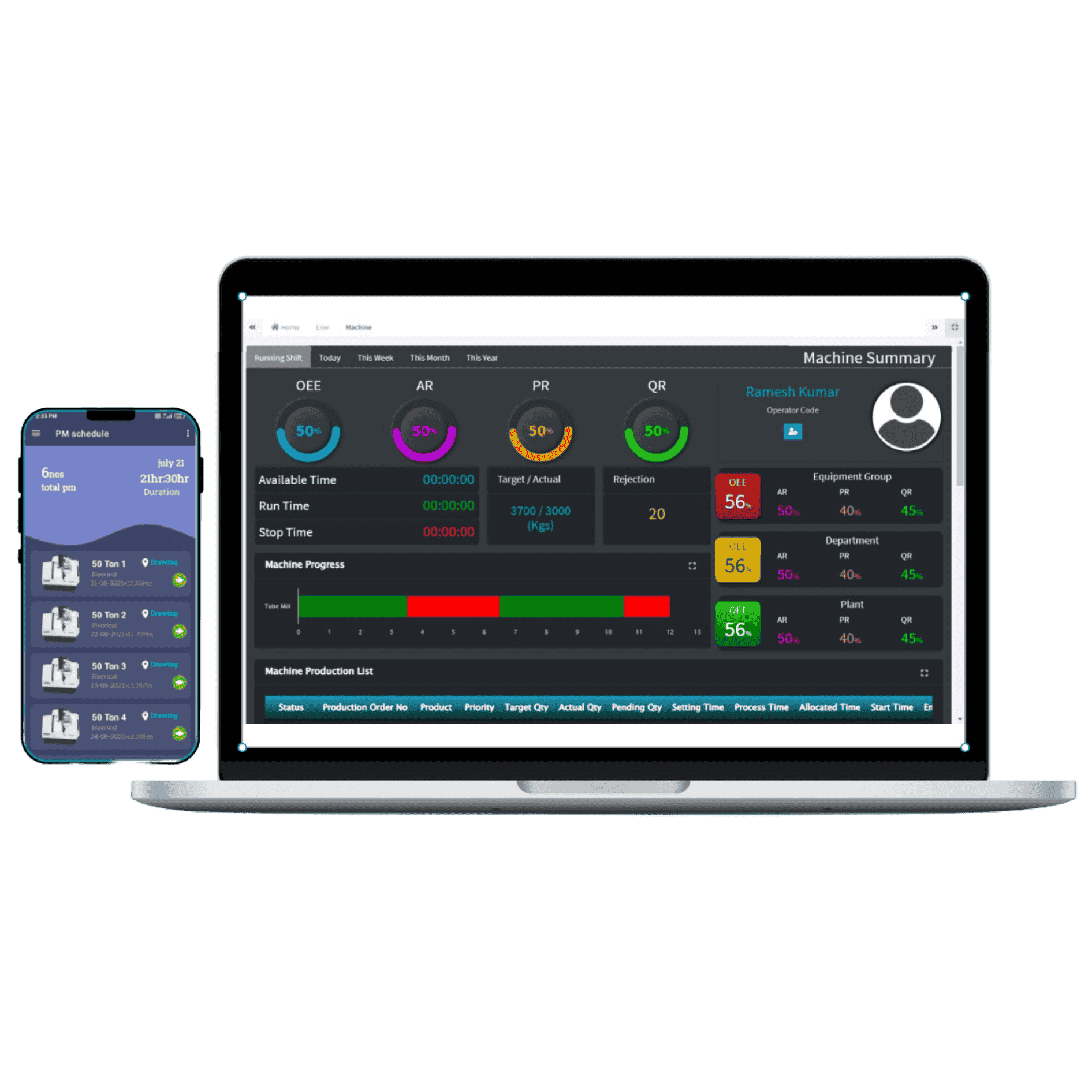

Smart Machines & Edge Computing

Read more -

Statistical Process Control (SPC)

Read more -

Production Planning, Production Scheduling & Capacity Planning (PPC)

Read more -

Warehouse Management System (WMS)

Read more -

Traceability

Read more -

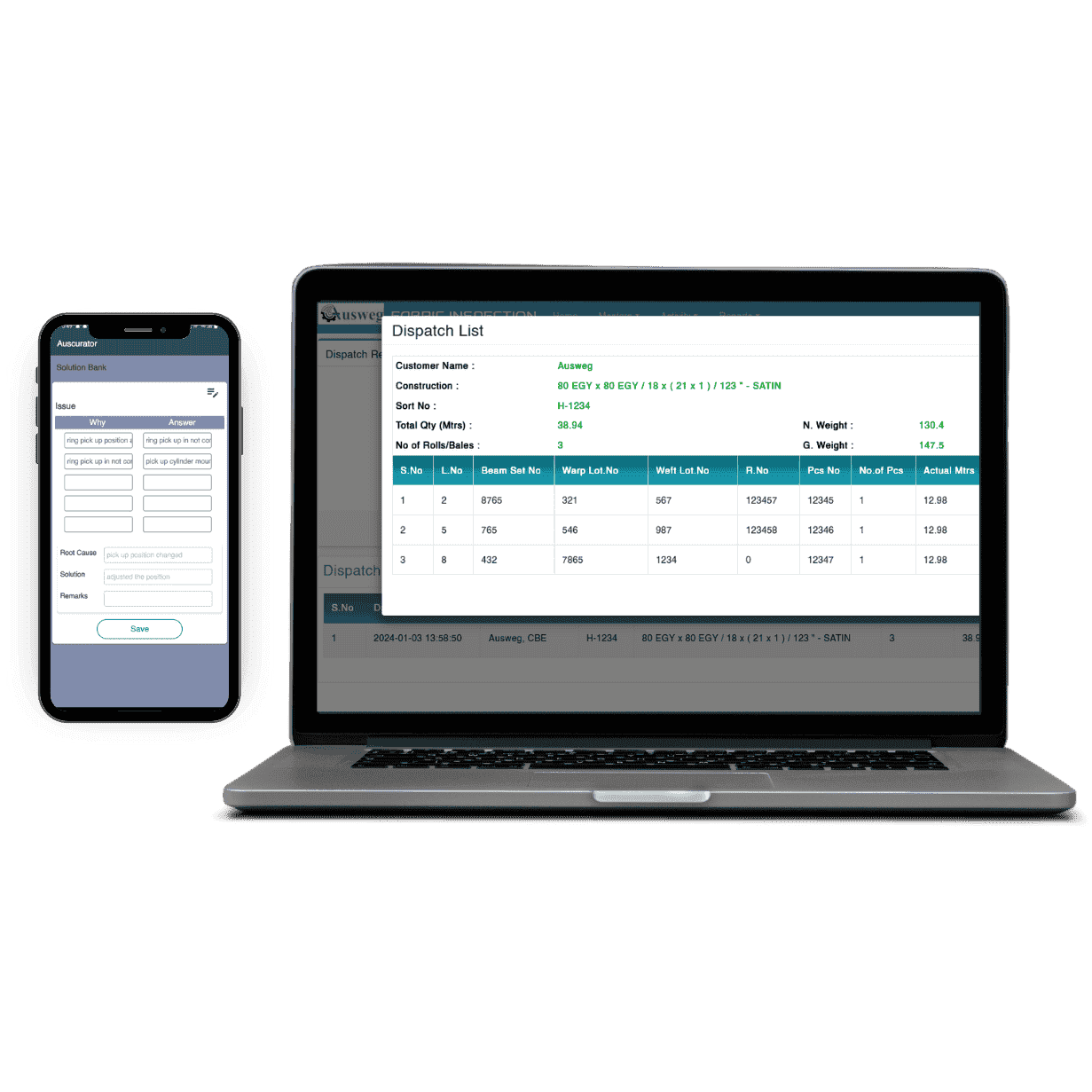

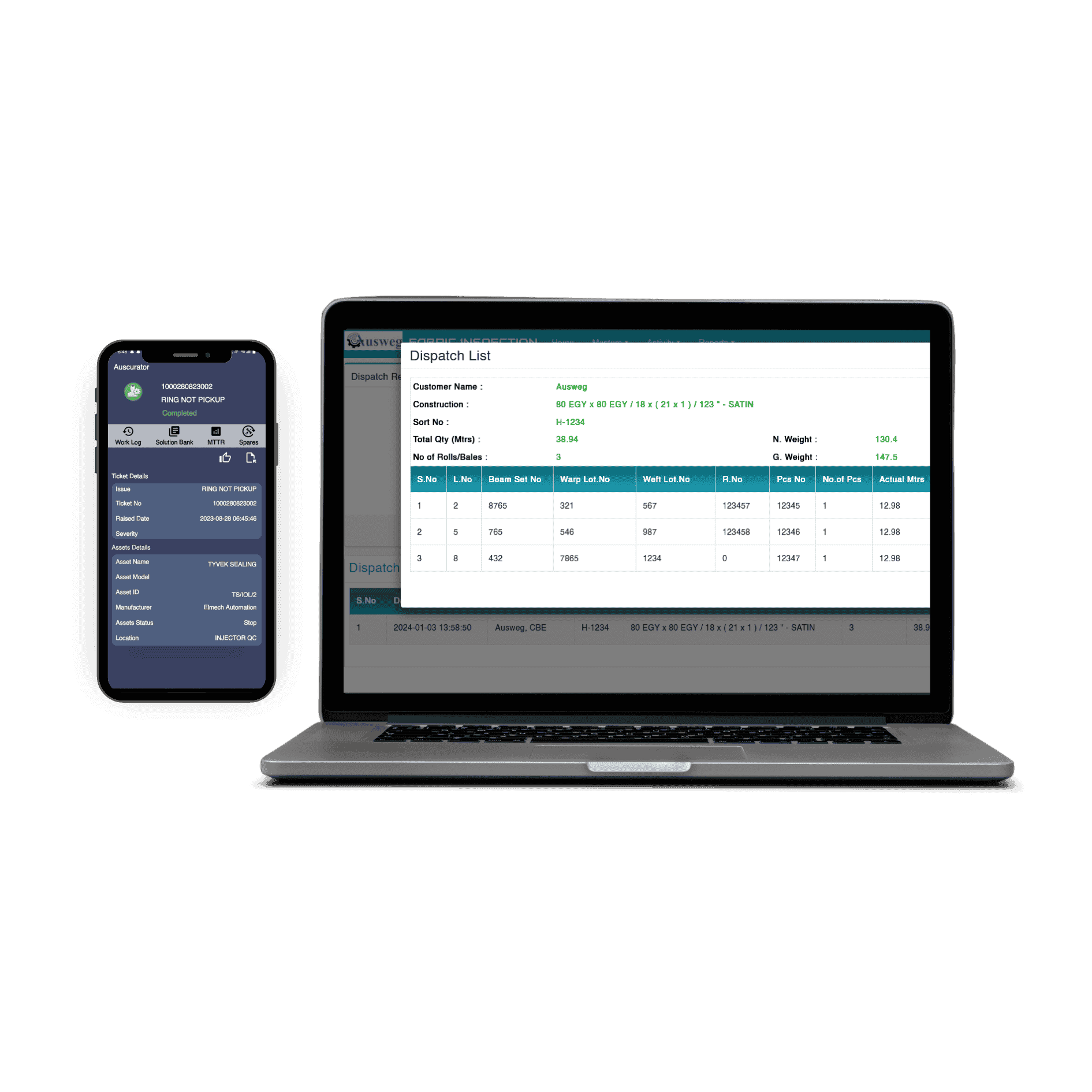

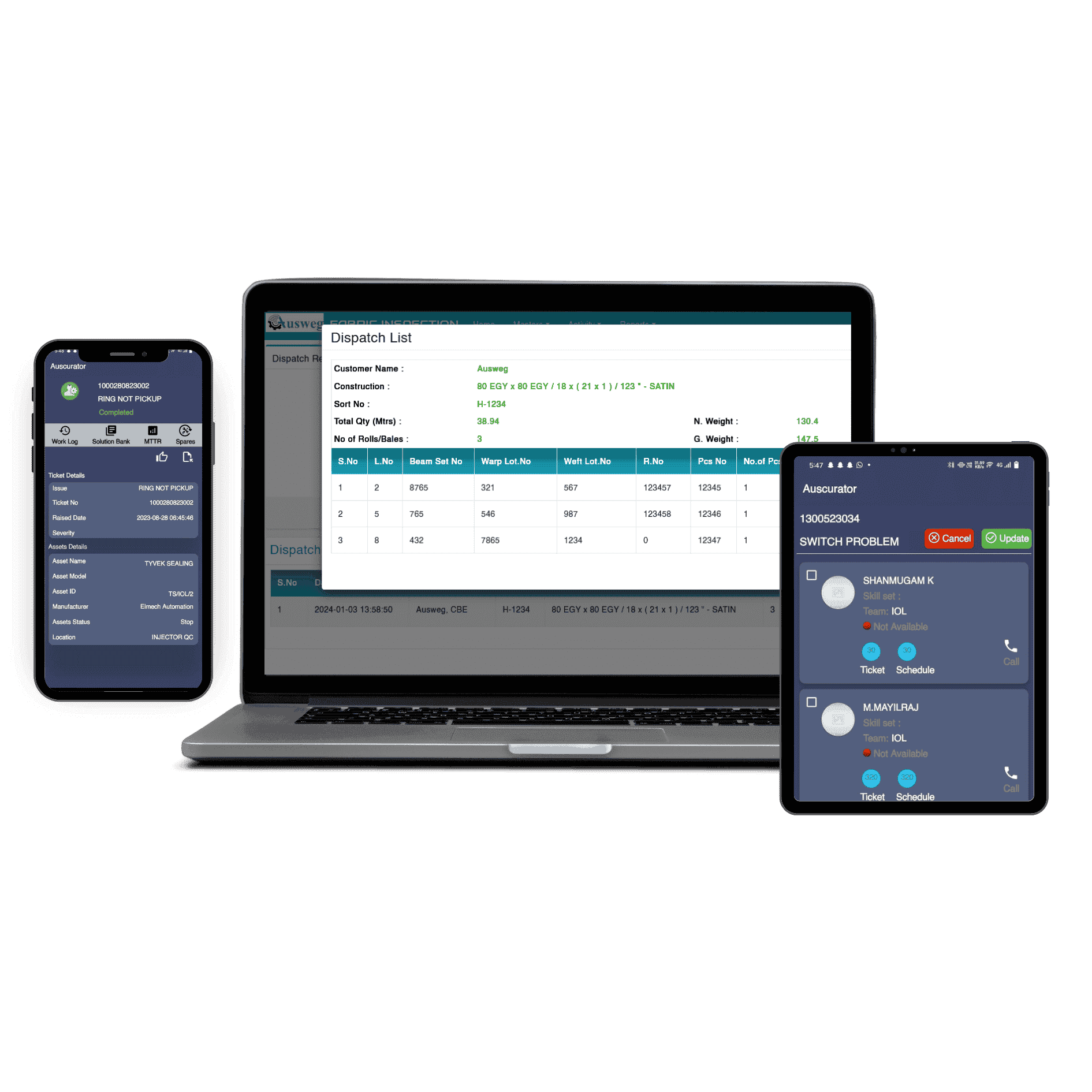

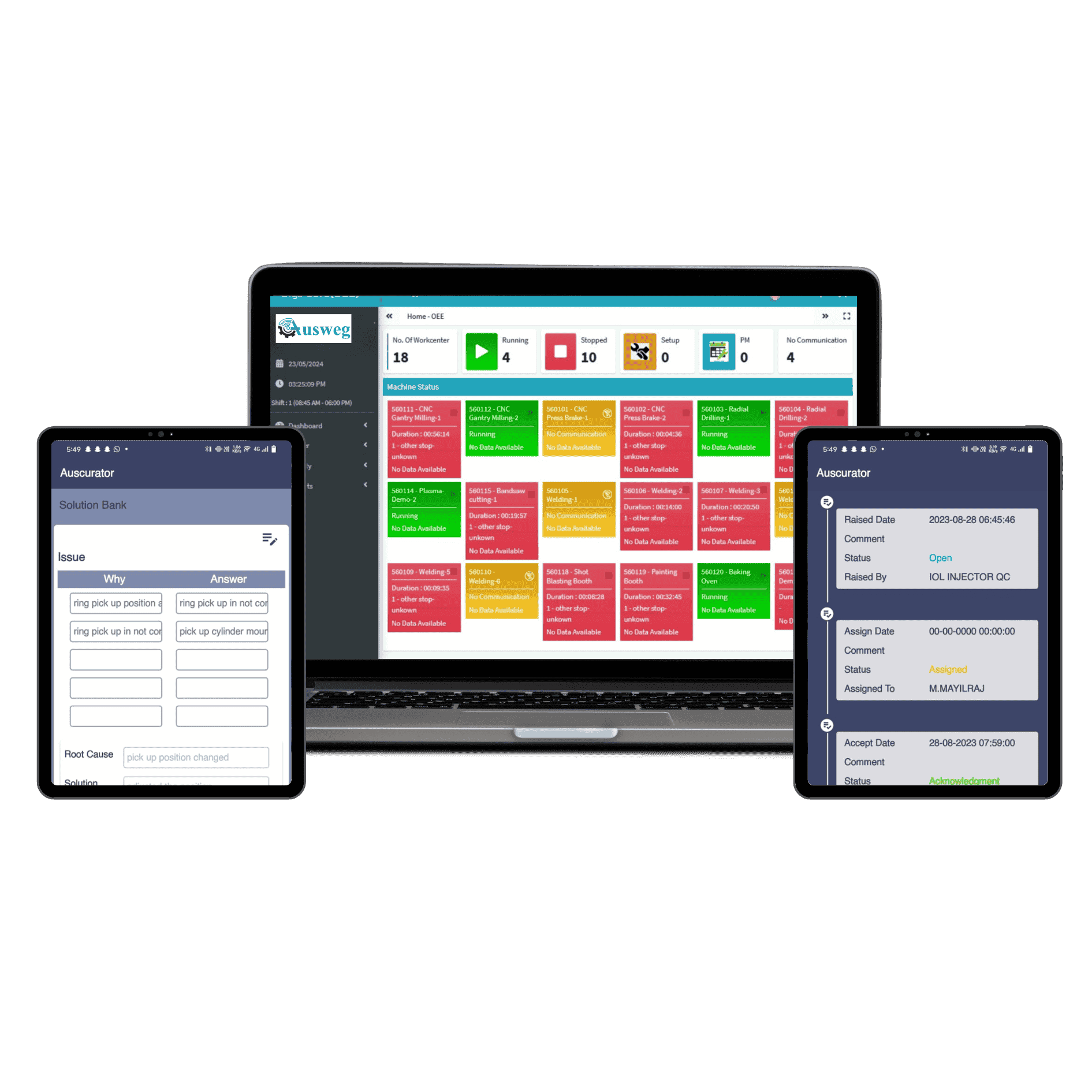

Computerized Maintenance Management System CMMS

Read more -

Condition Based Monitoring / Predictive Maintenance CBM / PdM

Read more -

Tool Monitoring

Read more -

Sewage Treatment Plant (STP) Monitoring

Read more -

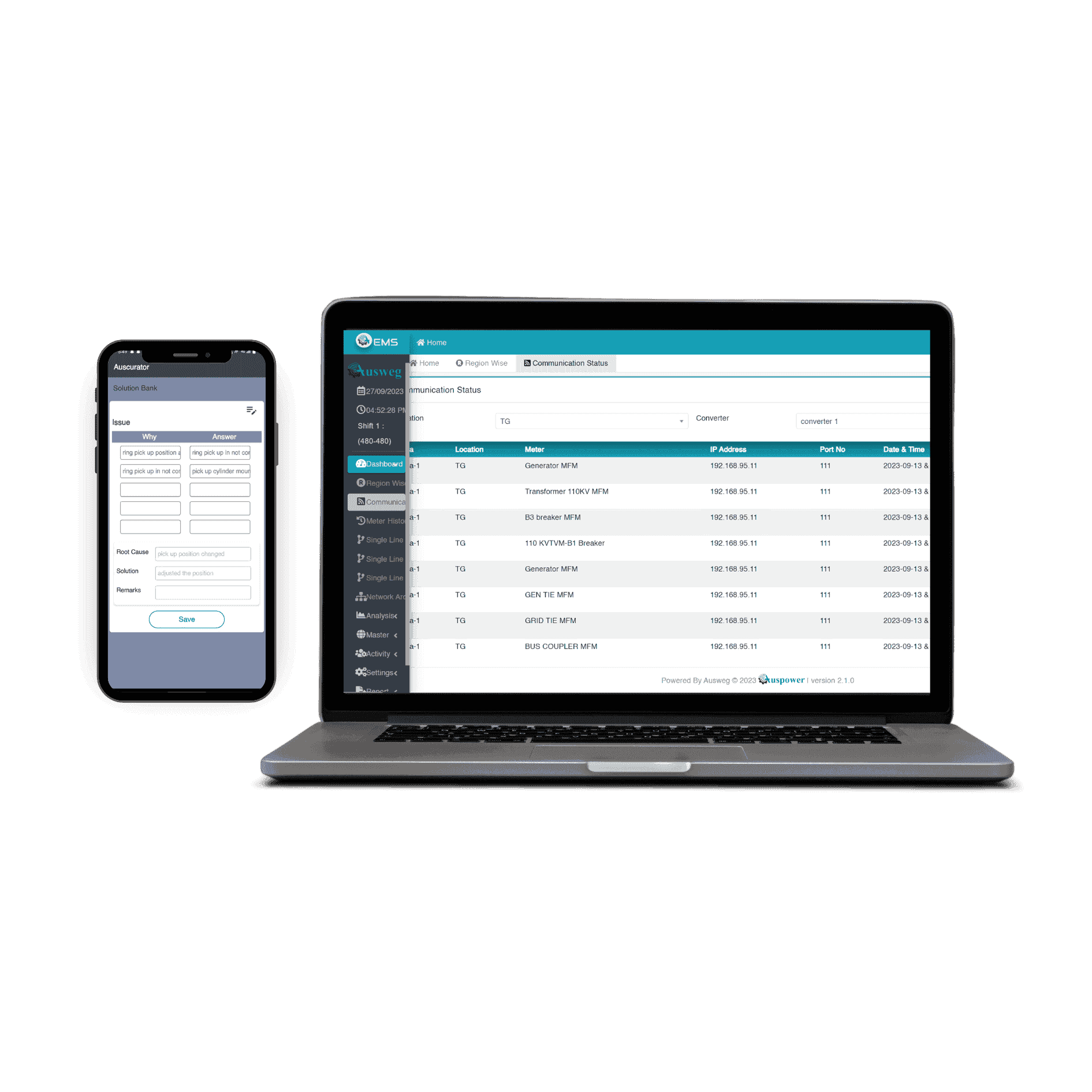

Energy Monitoring System- Empower, Optimize, Sustain

Read more -

Overall Equipment effectiveness OEE Monitoring

Read more

Frequently Asked Questions

We've compiled a list of answers to common questions.

IIoT refers to the interconnected network of Physical Devices, Sensors, and Software used in Industrial environments to Collect, Exchange, and Analyze data. This technology helps improve Operational efficiency, Optimize processes, and Enable Predictive Maintenance.

IIoT can benefit your manufacturing business by Enhancing operational efficiency, Reducing downtime, Improving product quality, Enabling predictive maintenance, and Providing real-time data for better decision-making.

IIoT systems can collect various types of data, including Machine Performance Metrics, Energy Consumption, Environmental Conditions, and Production Output, Among others.

The implementation timeline for IIoT solutions varies depending on the complexity of your operations, the number of machines involved, and your specific requirements. Typically, a phased approach is used to ensure minimal disruption.

Yes, our IIoT solutions are designed to be scalable, allowing you to start small and expand as your needs grow. Whether you want to monitor a single machine or an entire factory, our solutions can adapt to your requirements

Security is a top priority in our IIoT solutions. We implement Advanced encryption, Secure communication protocols, and Regular security updates to protect your data from unauthorized access and cyber threats

Yes, our IIoT solutions are designed to integrate seamlessly with your existing systems, including ERP, MES, and SCADA, ensuring a smooth transition and maximizing the value of your existing infrastructure

IIoT solutions are applicable across a wide range of industries, including Automotive, Aerospace, Electronics, Food & beverage, Pharmaceuticals, Oil & Gas, and more. Any industry with manufacturing or industrial processes can benefit from IIoT

The return on investment (ROI) for IIoT solutions varies based on the scope and scale of the implementation. However, many companies experience significant Cost savings, Reduced downtime, and Increased productivity, leading to a strong ROI within a short period.

Yes, we provide comprehensive support and training to ensure your team is fully equipped to use and maintain our IIoT solutions. Our support includes technical assistance, user training, and ongoing maintenance

Predictive maintenance uses IIoT technology to monitor the condition of equipment in real-time and predict when maintenance is needed before a failure occurs. This approach helps reduce unplanned downtime and extends the lifespan of your equipment.

IIoT solutions can monitor and analyze energy consumption across your facility, identifying areas of inefficiency and providing actionable insights to reduce energy waste, lower costs, and minimize your environmental impact.

IIoT implementation typically requires sensors, gateways, and connectivity infrastructure to collect and transmit data. We work with you to select and install the appropriate hardware for your specific needs

Yes, our IIoT solutions are highly customizable. We work closely with you to understand your unique requirements and tailor our solutions to meet your specific operational goals

The cost of implementing IIoT solutions depends on the scale and complexity of the project. We offer flexible pricing models, including subscription-based services, to fit your budget and needs

IIoT is a core component of Industry 4.0, enabling smart factories where machines, systems, and humans work together seamlessly. By adopting IIoT, you are paving the way for digital transformation and staying competitive in the evolving industrial landscape.

OEE (Overall Equipment Effectiveness) is a measure of how effectively your manufacturing operation is utilized. IIoT solutions provide real-time OEE monitoring, helping you identify bottlenecks and areas for improvement to maximize efficiency.

Our IIoT solutions are built on robust, industry-proven technology. We conduct thorough testing and offer continuous monitoring and support to ensure reliability and minimize downtime.

Yes, IIoT solutions can help ensure regulatory compliance by providing accurate, real-time data tracking and reporting. This is especially important in industries like pharmaceuticals and food & beverage, where compliance is critical.

The future of IIoT includes advancements in AI and machine learning, edge computing, 5G connectivity, and increased adoption of digital twins. These trends will further enhance the capabilities of IIoT, making it an even more powerful tool for industrial innovation.