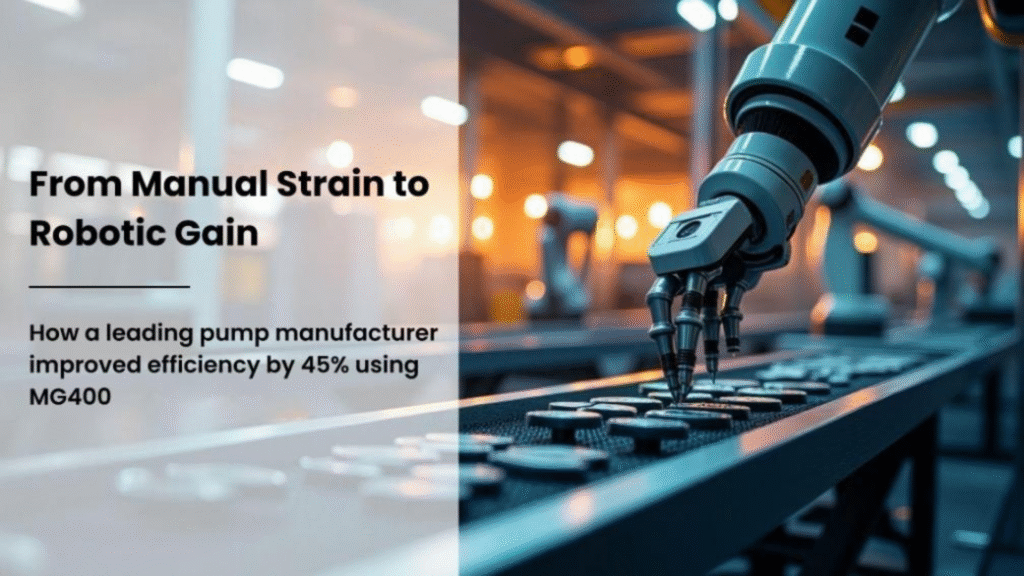

In the heart of Coimbatore, a hub for industrial innovation and engineering excellence, one of the leading pump manufacturing companies was struggling with a common yet critical challenge in their machine trimming process. Like many manufacturers, they were facing increasing pressure to improve productivity while ensuring operator safety and other problems. Learn more about the top industries using collaborative robots (Cobots) here.

The trimming process, a vital stage in pump manufacturing, involved repetitive loading and unloading tasks—physically exhausting for operators and hazardous due to the proximity to heavy machinery.

Recognizing the urgent need to modernize this labor-intensive process, the company partnered with Ausweg Info Controls — the Authorized Distributor of DOBOT Collaborative Robot (Cobot) in India — to implement a cutting-edge robotic solution. Leveraging our deep expertise in smart automation and robotics, we proposed the MG400 collaborative robot as the ideal fit for their trimming operations.

The core application: Loading and Unloading

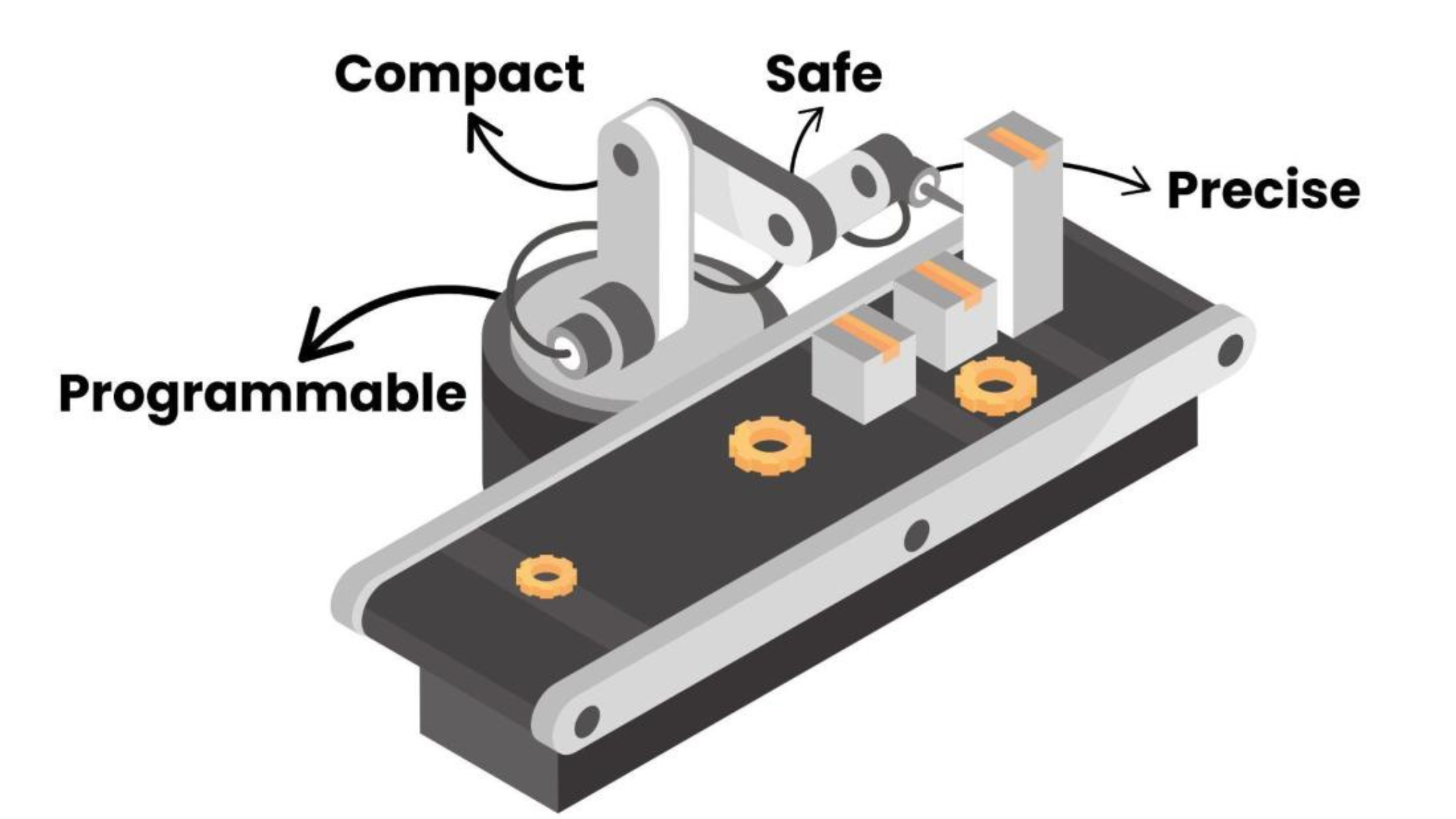

Our team deployed the compact and highly efficient MG400 robot to seamlessly pick components from a conveyor and place them into the trimming machine. Designed with high precision and adaptability, the MG400 offered a reliable, space-saving, and fully programmable solution that integrated smoothly with their existing production setup.

Challenges Faced

- The repetitive nature of the job made it physically fatiguing for human operators.

- Safety risks due to human involvement near operating machines.

- Lower production output, which constrained the company’s ability to meet growing demand.

Our Solution

With the MG400 in place, the process was fully automated. The robot was configured to handle continuous, repetitive loading and unloading tasks with unmatched consistency and precision.

Its user-friendly interface allowed the client to adjust operations effortlessly, while its collaborative design ensured safe deployment in close quarters.

Learn more about the MG400 robot here.

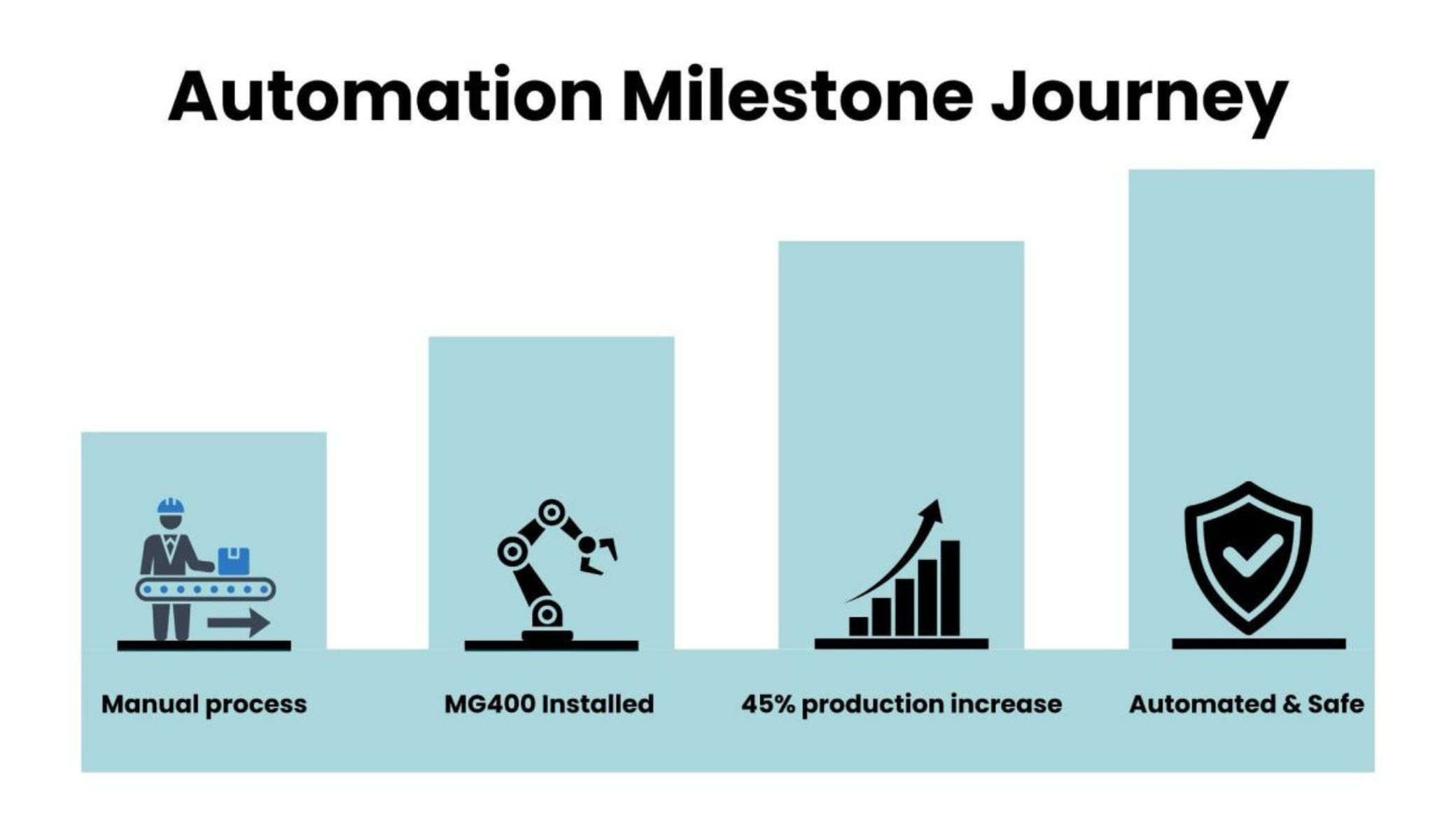

Impact & Results

- Production output increased from 257 components/hour to 385 components/hour.

- Production efficiency improved by 45%, helping the manufacturer meet delivery targets faster and more reliably.

- The trimming process is now completely unmanned, eliminating safety risks and allowing operators to focus on more skilled tasks.

- Enabled 24/7 production capability, opening the door for continuous operation without downtime.

This transformation not only addressed the client’s immediate challenges but also laid the foundation for future-ready, scalable automation. The MG400’s success in this trimming application underscores the power of smart robotics in modern manufacturing—especially in industries like pump manufacturing, where precision, safety, and speed are paramount.

By embracing robotics for applications such as loading and unloading, this leading Coimbatorebased manufacturer has set a new benchmark in operational excellence. Their journey stands as a testament to how automation with MG400 can reshape traditional production lines, delivering higher output, improved safety, and long-term efficiency.

Ready to Automate Your Process?

Join the growing number of manufacturers optimizing operations with MG400 robotic solutions. Whether you’re in pump manufacturing or any other high-volume industry, Ausweg Info Controls delivers smart automation that works.

Curious how the MG400 Collaborative Robot (Cobot) can transform your production line? Click here to know more

Leave a Reply