IIoT Solutions: Simple Guide to Smart Factory Technology

Smart factories are here. Industrial Internet of Things (IIoT) solutions help companies work better. These systems connect machines to computers. This makes work faster, safer, and cheaper.

What Is an IIoT Solution?

An IIoT solution connects your factory equipment to the internet. It uses sensors, software, and networks. These work together to collect data from your machines.

Think of it like this: Your machines can now “talk” to you. They tell you when they need repairs. They show you how to work better. They warn you about problems before they happen.

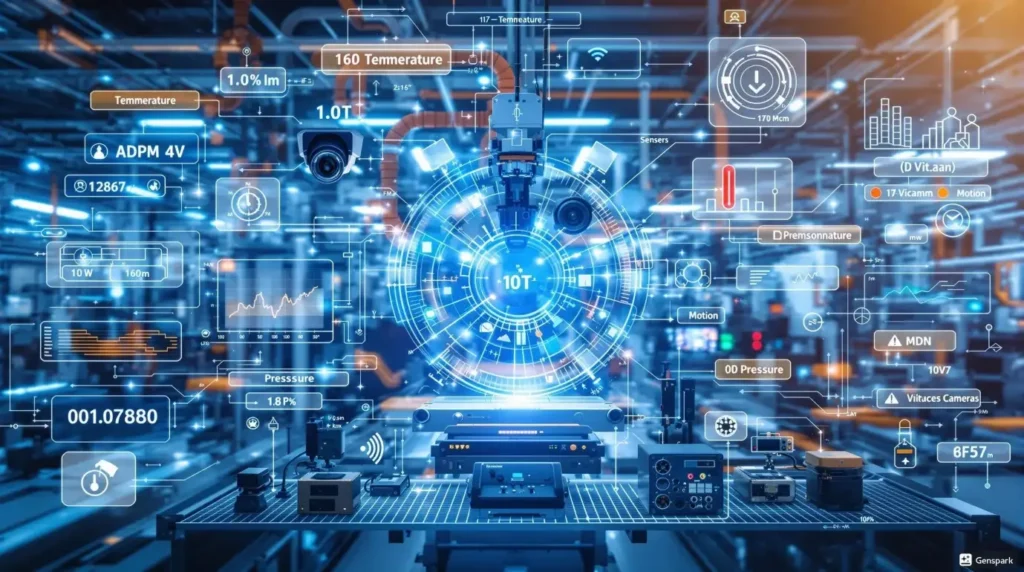

Main Parts of IIoT Systems

Every IIoT solution has four key parts:

Smart Sensors: These watch your machines. They check temperature, vibration, and pressure. They send this data to computers.

Networks: These carry data from sensors to computers. They use WiFi, cables, or cellular signals.

Software: This analyzes the data. It finds patterns and problems. It creates reports and alerts.

Apps: These show you what’s happening. Workers can see machine status on phones or tablets.

Types of Smart Sensors Used

Modern factories use many sensor types:

Temperature Sensors: These check if machines get too hot. Hot machines break down faster. These sensors prevent overheating.

Vibration Sensors: These feel when machines shake too much. Too much vibration means parts are wearing out. Early warning helps prevent breakdowns.

Pressure Sensors: These monitor fluid and air pressure. Wrong pressure can damage equipment. These sensors keep pressure at safe levels.

Motion Sensors: These track how machines move. They spot when movement patterns change. Changed patterns often mean problems.

Camera Systems: These watch for quality issues. They can spot defects humans might miss. They work 24 hours a day without getting tired.

Chemical Sensors: These test air and water quality. They help companies follow environmental rules. They protect worker health.

How Data Moves Through Your System

Data travels from sensors to decision-makers in stages:

Collection: Sensors gather information every second. This creates lots of data very quickly.

Transmission: Networks send data to computers. Fast networks mean real-time information.

Processing: Computers analyze the data. They look for problems and opportunities.

Action: Systems automatically respond to issues. Or they alert humans to take action.

Industry Applications That Work

Manufacturing Success Stories

Factories use IIoT solutions for many purposes: (Predictive maintenance in manufacturing)

Predictive Maintenance: Systems predict when machines will break. This prevents surprise breakdowns. Companies save 15-30% on maintenance costs. Downtime drops by 25-50%.

Quality Control: Cameras and sensors check every product. They catch defects immediately. This reduces waste and customer complaints.

Energy Management: Smart systems turn off unused equipment. They optimize heating and cooling. Companies typically save 5-15% on energy bills.

Worker Safety: Sensors monitor dangerous gases and temperatures. They alert workers to hazards. Automatic systems can shut down unsafe equipment.

Inventory Tracking: RFID tags track parts and products. Systems know exactly what’s in stock. This prevents shortages and overordering.

Food and Beverage Industry

Food companies use IIoT for safety and quality:

Temperature Monitoring: Sensors track food temperature throughout production. This prevents spoilage and contamination.

Traceability: Systems track ingredients from farm to customer. This helps during food safety recalls.

Cleaning Verification: Sensors confirm equipment is properly cleaned. This prevents contamination between batches.

Oil and Gas Operations

Energy companies rely on IIoT for safety and efficiency:

Pipeline Monitoring: Drones with sensors inspect pipelines. They find leaks before they become dangerous.

Well Optimization: Sensors in oil wells optimize production. They adjust pumping based on reservoir conditions.

Refinery Safety: Gas sensors monitor for dangerous leaks. Automatic systems shut down equipment if needed.

Utilities and Power

Electric companies use IIoT for grid management:

Smart Meters: These track energy use in real-time. They help balance supply and demand.

Transformer Monitoring: Sensors watch transformer health. They prevent expensive equipment failures.

Renewable Integration: Systems balance wind and solar power. They store excess energy for later use.

Step-by-Step Implementation Guide

Phase 1: Planning Your Project

Start with these important steps:

Identify Problems: What issues cost your company the most money? Focus IIoT solutions on these areas first.

Set Clear Goals: Define exactly what you want to achieve. Examples: “Reduce downtime by 20%” or “Cut energy costs by 10%.”

Calculate ROI: Estimate costs and benefits. Most companies see payback within 12-24 months.

Choose Your Team: Include people from operations, IT, and management. Everyone needs to support the project.

Budget Planning: IIoT projects typically cost $50,000 to $500,000. Start small and expand over time.

Phase 2: Pilot Project

Begin with a small test project:

Pick One Area: Choose a single production line or piece of equipment. Learn from this before expanding.

Install Basic Sensors: Start with temperature and vibration monitoring. These provide immediate value.

Connect to Network: Set up secure data transmission. Use existing WiFi or install new networks.

Train Operators: Teach workers how to use new dashboards and alerts. Get their feedback and suggestions.

Measure Results: Track improvements carefully. Use these results to justify bigger investments.

Phase 3: Scaling Up

After pilot success, expand your system:

Add More Equipment: Connect additional machines and production lines. Use lessons learned from the pilot.

Integrate Systems: Connect IIoT data to existing software. This might include ERP, MES, or SCADA systems.

Advanced Analytics: Add predictive analytics and machine learning. These provide deeper insights over time.

Cross-Site Deployment: Roll out successful solutions to other facilities. Standardize approaches for consistency.

Continuous Improvement: Keep updating and improving systems. Technology changes quickly in this field.

Real Benefits Companies See

Cost Reduction Results

Companies report these typical savings:

Maintenance Costs: 15-30% reduction through predictive maintenance. Fixing problems before they break equipment saves money.

Energy Costs: 5-15% reduction through smart energy management. Systems automatically optimize power usage.

Labor Costs: 10-25% reduction through automation. Workers focus on higher-value tasks instead of routine monitoring.

Inventory Costs: 20-30% reduction through better tracking. Companies avoid overordering and stockouts.

Insurance Costs: 5-10% reduction through improved safety. Fewer accidents mean lower premiums.

Operational Improvements

Beyond cost savings, companies see:

Equipment Uptime: Increases from 85% to 95% or higher. Less downtime means more production.

Product Quality: Defect rates drop by 20-50%. Consistent quality improves customer satisfaction.

Worker Productivity: Increases by 10-20%. Better information helps workers make faster decisions.

Compliance: Automated reporting makes regulatory compliance easier. Systems track everything automatically.

Customer Satisfaction: Improves through better quality and delivery. Happy customers buy more and refer others.

Safety Enhancements

IIoT solutions make workplaces safer:

Accident Prevention: Sensors detect dangerous conditions before accidents happen. Workers get warnings in time to stay safe.

Emergency Response: Systems automatically call for help during emergencies. Faster response saves lives and reduces damage.

Health Monitoring: Air quality sensors protect worker health. They detect harmful gases and particles.

Training Improvement: Data shows where safety training is needed most. Companies can focus training efforts effectively.

Security and Safety Concerns

Protecting Your Investment

IIoT systems need strong security:

Network Security: Use firewalls and encryption to protect data. Separate industrial networks from office networks.

Device Security: Change default passwords on all devices. Use strong, unique passwords for each device.

Access Control: Only give people access to what they need. Track who accesses what information and when.

Regular Updates: Keep software updated with latest security patches. Old software has known vulnerabilities.

Backup Plans: Have plans for when systems fail. Know how to operate manually if needed.

Industry Standards to Follow

Follow these important security guidelines: (NIST cybersecurity framework)

NIST Framework: Provides comprehensive cybersecurity guidance. Most companies use this as their foundation.

IEC 62443: Specifically designed for industrial control systems. Covers network security and device protection. (IEC 62443 standard)

ISO 27001: International standard for information security. Helps organize security management programs. (ISO 27001 information security standard)

Industry Rules: Follow regulations specific to your industry. Healthcare, finance, and energy have special requirements.

Common Security Mistakes

Avoid these frequent problems:

Default Passwords: Never leave default passwords on devices. Hackers know these passwords and use them.

No Network Separation: Don’t connect industrial systems directly to the internet. Use secure gateways and firewalls.

Delayed Updates: Don’t postpone security updates. Schedule regular maintenance windows for updates.

Poor Training: Don’t assume employees know about security. Provide regular training on threats and best practices.

No Incident Plans: Don’t wait for attacks to happen. Have response plans ready before you need them.

Future Technology Trends

Artificial Intelligence Integration

AI makes IIoT systems smarter:

Machine Learning: Systems learn from data patterns. They get better at predicting problems over time.

Computer Vision: Cameras powered by AI spot defects humans miss. They work faster and more consistently.

Natural Language: Workers can ask systems questions in plain English. No need to learn complex interfaces.

Automated Optimization: AI systems automatically adjust processes. They find the best settings without human input.

5G Network Technology

New wireless networks enable better IIoT:

Faster Speeds: Download data 100 times faster than current networks. Real-time monitoring becomes truly real-time. (5G and IIoT integration)

More Devices: Support millions of connected devices per square mile. No limits on sensor density.

Lower Delays: Response times under 1 millisecond. Fast enough for safety-critical applications.

Better Coverage: Works reliably in industrial environments. Strong signals penetrate buildings and interference.

Edge Computing Advances

Processing data closer to machines:

Instant Response: No delays waiting for cloud processing. Critical decisions happen immediately.

Reduced Bandwidth: Less data travels to central servers. This reduces network costs and congestion.

Better Reliability: Systems work even when internet connections fail. Local processing keeps operations running.

Enhanced Privacy: Sensitive data stays local instead of traveling to remote servers. This improves security and compliance.

The global IIoT market will reach $286.3 billion by 2029. Growth rate is 8.1% per year as more companies adopt these technologies. (IIoT market growth forecast)

Choosing the Right Partner

What to Look for in Vendors

Select IIoT providers based on:

Industry Experience: Choose companies that understand your specific industry. They know common problems and proven solutions.

Technical Expertise: Look for teams with both IT and operational technology skills. IIoT requires knowledge of both areas.

Security Focus: Ensure vendors take security seriously. Ask about their security certifications and practices.

Support Services: Choose providers that offer ongoing support. IIoT systems need regular maintenance and updates.

Scalability: Select solutions that can grow with your business. Avoid vendors that limit expansion options.

Questions to Ask Vendors

Before choosing a partner, ask:

- How long have you been implementing IIoT solutions?

- Can you provide references from similar companies?

- What security measures do you include?

- How do you handle system maintenance and updates?

- What happens if your company goes out of business?

- Can your solution integrate with our existing systems?

- What training do you provide for our employees?

- How quickly can you respond to support requests?

Implementation Timeline

Typical IIoT projects follow this schedule:

Months 1-2: Planning and design phase. Define requirements and select technology.

Months 3-4: Pilot installation and testing. Start with small-scale implementation.

Months 5-6: Pilot optimization and training. Fine-tune systems and train users.

Months 7-12: Full-scale deployment. Roll out to entire facility or multiple sites.

Ongoing: Continuous improvement and expansion. Add features and connect more equipment.

Making IIoT Work for You

Industrial Internet of Things solutions offer real benefits for companies ready to modernize. Success comes from careful planning, choosing the right partners, and starting with manageable projects.

The key is understanding that IIoT is not just about technology. It changes how people work, how decisions get made, and how companies compete. Organizations that embrace this change see the biggest benefits.

Start by identifying your most expensive problems. Then find IIoT solutions that address these specific issues. Measure results carefully and use success to justify expanding the program.

Remember that IIoT implementation takes time. Most companies need 12-18 months to see full benefits. But early wins often appear within 3-6 months of starting pilot projects.

The companies that wait too long risk falling behind competitors. IIoT adoption is accelerating rapidly across all industries. First movers gain significant advantages that become harder to overcome over time.

Ready to Start Your IIoT Journey?

Transform your operations with proven IIoT technology designed for your industry. Our team has helped hundreds of companies implement smart solutions that deliver measurable results.

We start with a free assessment of your current operations. This identifies the best opportunities for IIoT implementation. Then we design a custom solution that fits your budget and timeline.

Our approach focuses on quick wins that build momentum for larger projects. You see benefits within months, not years. And our ongoing support ensures your systems keep delivering value.

Schedule your free consultation today. Discover how IIoT solutions can reduce your costs, improve your safety, and give you competitive advantages in your market.

Don’t wait for competitors to get ahead. Call us now or visit our website to start your digital transformation. Your future success depends on the decisions you make today.

Leave a Reply