At Ausweg, we’re seeing this shift firsthand as manufacturers rethink how work gets done on the shop floor. Let’s break down why industrial robotics adoption is scaling faster than ever — and why now is the moment to act.

The Competitive Imperative: Speed, Quality, and Consistency

Indian manufacturers are under constant pressure to deliver higher quality at lower costs, without compromising timelines. Industrial robots enable:

- Consistent production throughput, 24/7

- Repeatable precision, eliminating quality drift

- Scalable operations, even with frequent product changeovers

At Ausweg, we help manufacturers deploy robotics not as isolated machines, but as integrated production enablers aligned to real business outcomes.

Workforce Challenges Are Driving Smart Automation

Labour availability, rising skill gaps, and operator fatigue are becoming operational risks. Robots are stepping in to:

- Handle repetitive, hazardous, and high-precision tasks

- Reduce dependency on manual labor for consistency-critical operations

- Enable human teams to focus on supervision, optimization, and innovation

This isn’t workforce replacement — it’s workforce elevation, and Indian factories are embracing it fast.

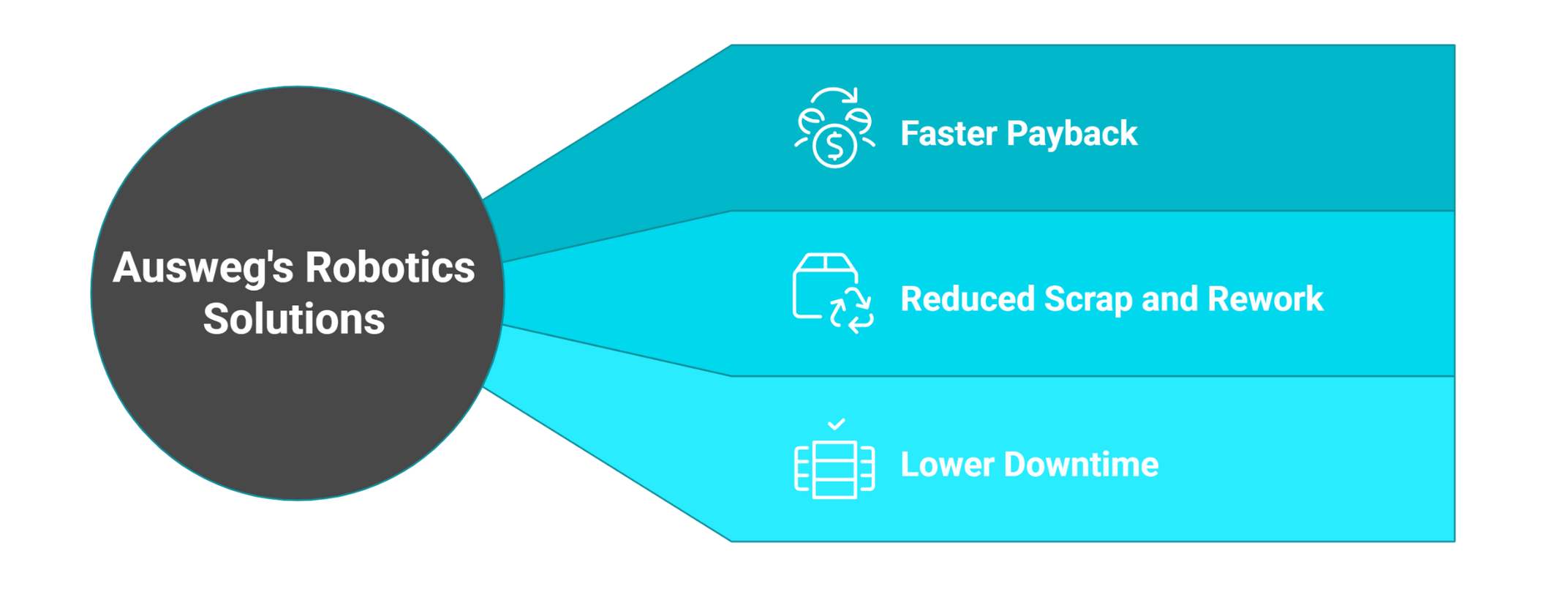

ROI Is No Longer a Question Mark

One of the biggest blockers to robotics adoption used to be cost. In 2026, that narrative is outdated.

With optimized robot selection, right payload sizing, and application-specific design — ROI timelines are shorter than ever.

Manufacturers working with Ausweg are achieving:

- Faster payback through productivity gains

- Reduced scrap and rework costs

- Lower downtime with predictive and condition-based maintenance

Automation today is a financially strategic move, not a capex gamble. Still wondering how robotics fits into real shop-floor scenarios? See how Ausweg implemented an industrial robotics solution for a real manufacturing application → [Read the Case Study]

Robotics + IIoT = Smart Factory Advantage

Robotics adoption is accelerating because it’s tightly coupled with Industry 4.0 and IIoT.

When robots are connected to:

- OEE monitoring systems

- Energy and performance dashboards

- Predictive analytics platforms

Manufacturers gain real-time visibility and data-driven control over their operations.

Ausweg specializes in bridging OT and IT, ensuring robots don’t just work — they communicate, adapt, and optimize.

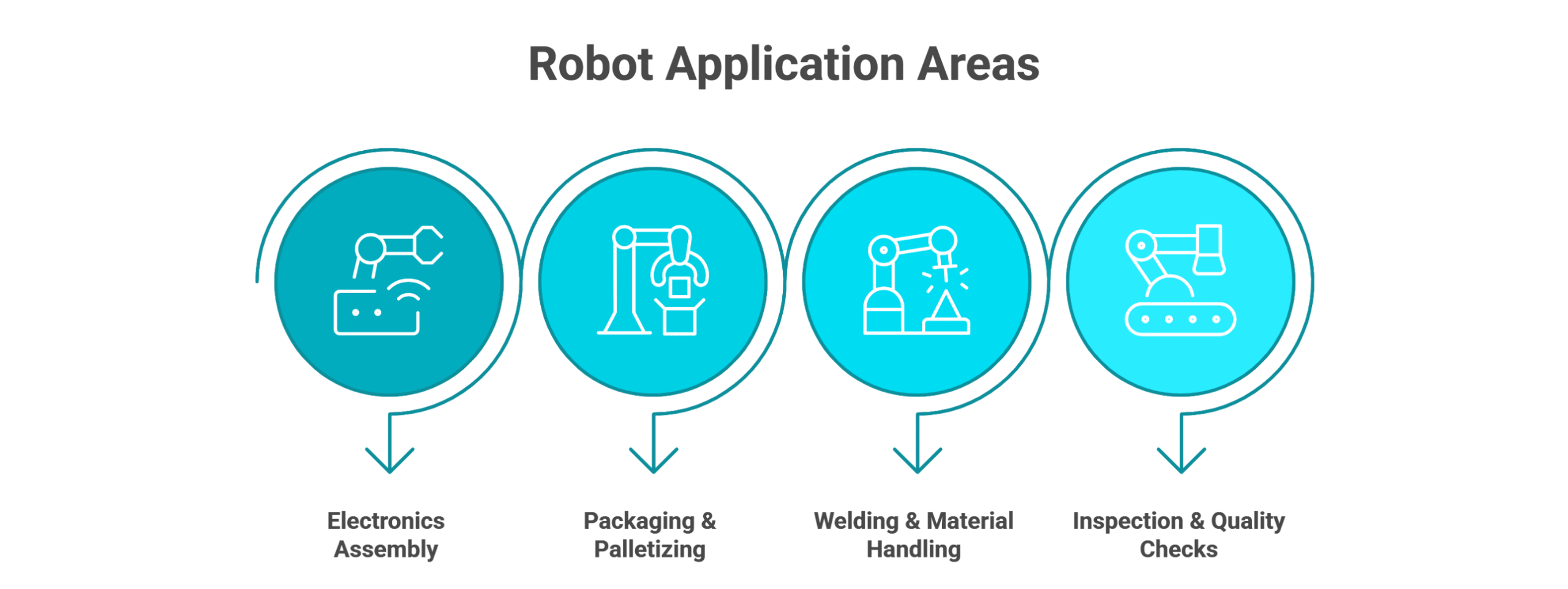

Wider Application, Lower Entry Barriers

Modern industrial robots are no longer limited to automotive giants. Adoption is booming across:

- Electronics assembly

- Packaging & palletizing

- Welding & material handling

- Inspection and quality checks

With flexible configurations and modular integration, even mid-sized manufacturers can deploy robotics without disrupting existing workflows — a sweet spot where Ausweg delivers maximum value.

Policy Push and Market Momentum

Initiatives like Make in India and production-linked incentives are pushing manufacturers toward productivity-led growth. Robotics directly supports:

- Higher output with controlled costs

- Export-quality manufacturing standards

- Faster scaling without proportional manpower increase

As policy tailwinds align with technology maturity, robotics adoption is only accelerating.

What Indian Manufacturers Are Really Achieving

Beyond buzzwords, here’s what robotics adoption is delivering on the ground:

Stable Production

Consistent production rates across all shifts

Superior Quality

Improved product quality and compliance

Reduced Downtime

Predictable maintenance schedules

Market Agility

Faster response to market demand

These outcomes explain why robotics is no longer a future plan — it’s a 2026 priority.

Building the Factory of the Future, Today

Industrial robotics is redefining how Indian factories compete, scale, and sustain growth. Manufacturers who act now aren’t just automating — they’re future-proofing their operations.

In 2026, robotics is no longer a future roadmap item. It’s a strategic priority for manufacturers who want consistent quality, predictable output, and the agility to respond to fast-changing market demands.

Ready to Future-Proof Your Factory?

Ausweg helps manufacturers design and deploy industrial robotics solutions that drive productivity, quality, and real business impact—without disrupting production.

👉 Talk to Our Robotics Experts

Leave a Reply